Avda. Los Pajaritos 3195, Oficina 1410

Edificio Centro Maipú

Maipú – Santiago

Avda. Los Pajaritos 3195, Oficina 1410

Edificio Centro Maipú

Maipú – Santiago

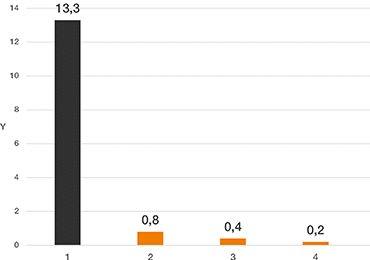

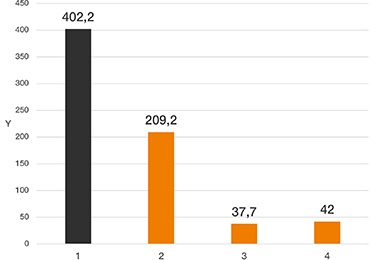

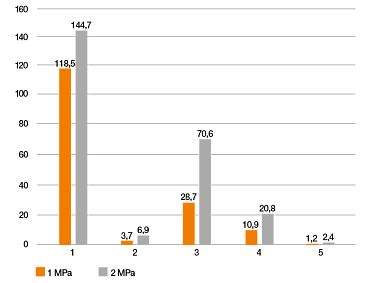

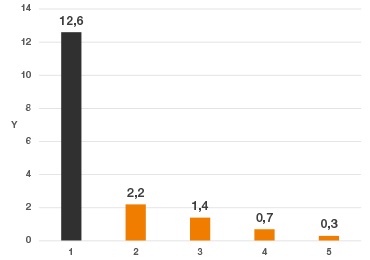

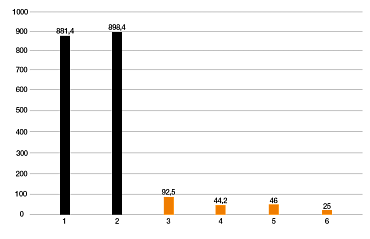

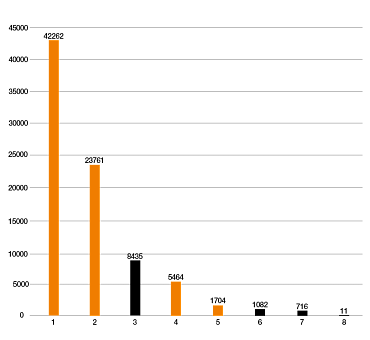

Y= índice de desgaste [µm/km]

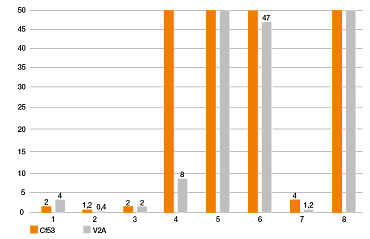

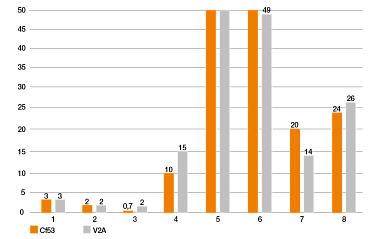

Eje x: materiales de prueba

Resultado de la prueba:

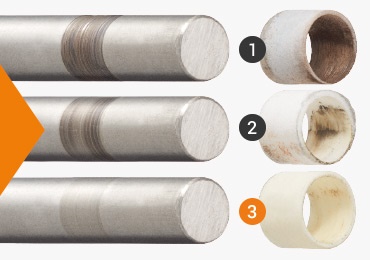

Durante la prueba de giro, las propiedades tribológicas de los filamentos de iglidur permitieron una resistencia al desgaste hasta 50 veces superior a la de los materiales de impresión 3D convencionales, como el ABS. El polímero resistente al desgaste garantiza una vida útil mucho más larga de los cojinetes de fricción y otros componentes.

¿Cuánto durará un cojinete iglidur impreso en su aplicación? Solo tiene que introducir los requisitos y determinar la vida útil online con el calculador gratuito de la vida útil de los cojinetes de fricción.

Parámetros de la prueba:

Eje y: índice de desgaste [µm/km]

Eje x: materiales de prueba

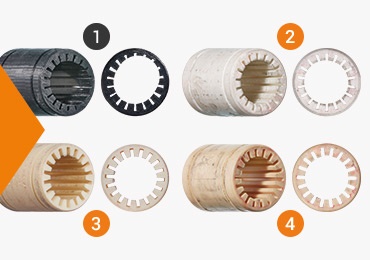

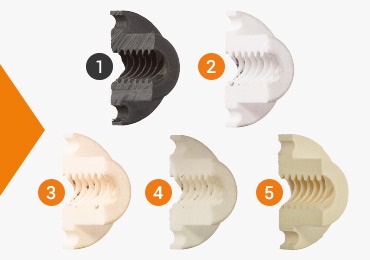

1. iglidur I3 (impresión 3D SLS)

2. iglidur I180 (impresión 3D FDM)

3. iglidur G (inyección)

4. iglidur W300 (inyección)

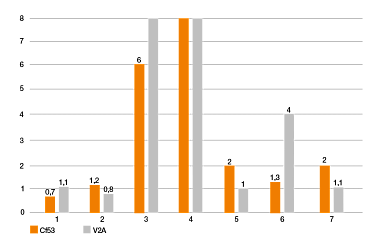

Parámetros de la prueba:

Parámetros de la prueba:

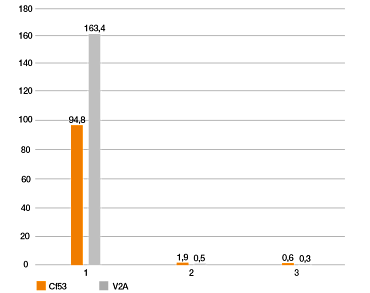

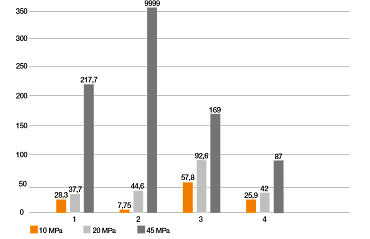

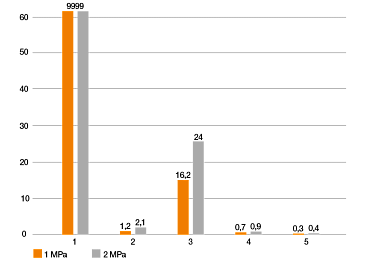

Parámetros de prueba:

pivoting oscilación 1.440°:

n = 64 r. p. m.

M = 2,25 Nm

z= 30

m= 1

b = 6 mm

Parámetros de la prueba:

De lunes a viernes de 7:00 a 20:00Sábados de 8:00 a 12:00

24h