Avda. Los Pajaritos 3195, Oficina 1410

Edificio Centro Maipú

Maipú – Santiago

Avda. Los Pajaritos 3195, Oficina 1410

Edificio Centro Maipú

Maipú – Santiago

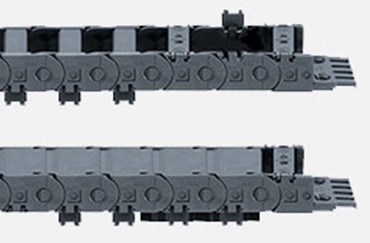

Resistente a las virutas, el polvo y la suciedad

Sin lubricación ni mantenimiento

Sistemas de cadenas portacables confeccionados y listos para instalar

Instalación rápida

Minimice los tiempos de parada

Montaje fácil

Alta resistencia y solidez

Funcionamiento silencioso

Cables con una vida útil larga

Resistente, silencioso, modular

Montaje rápido

Posibilidad de carreras largas

Larga vida útil

Cables a prueba de fallos

Garantía de 36 meses

Apto para condiciones ambientales extremas

Instalación rápida

Reducción de fallos

Sin cables sobrantes

Sistema «Plug & Play»

100 % libre de lubricación

Resistentes a la corrosión e higiénicos

Resistentes al desgaste

Funcionamiento extremadamente silencioso

Sin lubricación ni mantenimiento

Resistente a la corrosión

Resistentes a la suciedad

Funcionamiento silencioso

Este torno fabricado por HOMAG India procesa las partes de madera, lo que genera una gran cantidad de virutas y polvo. El uso de los cojinetes de fricción iglidur®, que contienen un lubricante sólido, permite que los cojinetes de las máquinas requieran poco mantenimiento yno necesiten lubricarse. Lo que supone un ahorro en los costes y en el tiempo de servicio, a la vez que previene que las virutas y el polvo se enganchen en los cojinetes.

De lunes a viernes de 7:00 a 20:00Sábados de 8:00 a 12:00

24h