Avda. Los Pajaritos 3195, Oficina 1410

Edificio Centro Maipú

Maipú – Santiago

Avda. Los Pajaritos 3195, Oficina 1410

Edificio Centro Maipú

Maipú – Santiago

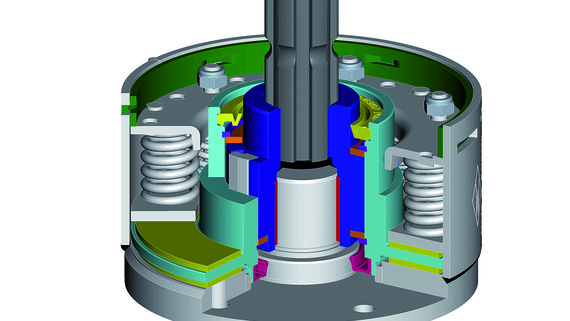

Due to the changes in agriculture, the demands on machinery and equipment for cultivating farmland are constantly increasing. As a supplier of drive systems for agricultural machinery, GKN Walterscheid GmbH is constantly working on adapting its products to meet these requirements. In this project, an existing combined overload clutch (combination of friction clutch and freewheel clutch) was revised. This is used in a disc mower to limit short-term torque peaks.

The problem arises from the demand for higher speeds of up to 1300 revolutions per minute. The standard design of the friction freewheel clutch is relatively prone to play, which leads to uneven operating characteristics at high speeds. As these clutches have already been used in many applications, it was important for GKN Walterscheid GmbH to create a solution with a new bearing concept that enables a 1:1 replacement of the old clutch.

As the application in agriculture takes place under the most adverse conditions and the components are exposed to substances such as fertilisers, a robust solution had to be found. Added to this are high temperatures, especially in conjunction with a friction clutch.

De lunes a viernes de 7:00 a 20:00Sábados de 8:00 a 12:00

24h